It is important to check the instructions that are provided by individual manufacturers for installing their roofing sheets. This is particularly relevant if a guarantee is offered, as it is generally mandatory to have followed the manufacturers' instructions correctly if you are planning to make a claim.

Step 1 - If possible, cut and prepare the sheets before starting the installation. This includes pre-drilling any holes that are required for fixing to purlins or the decking beneath.

Step 2 - Start laying the first sheet at the opposite end of the roof to the prevailing wind. Ensure that the eaves and verge are overlapped to prevent unnecessary exposure to the weather.

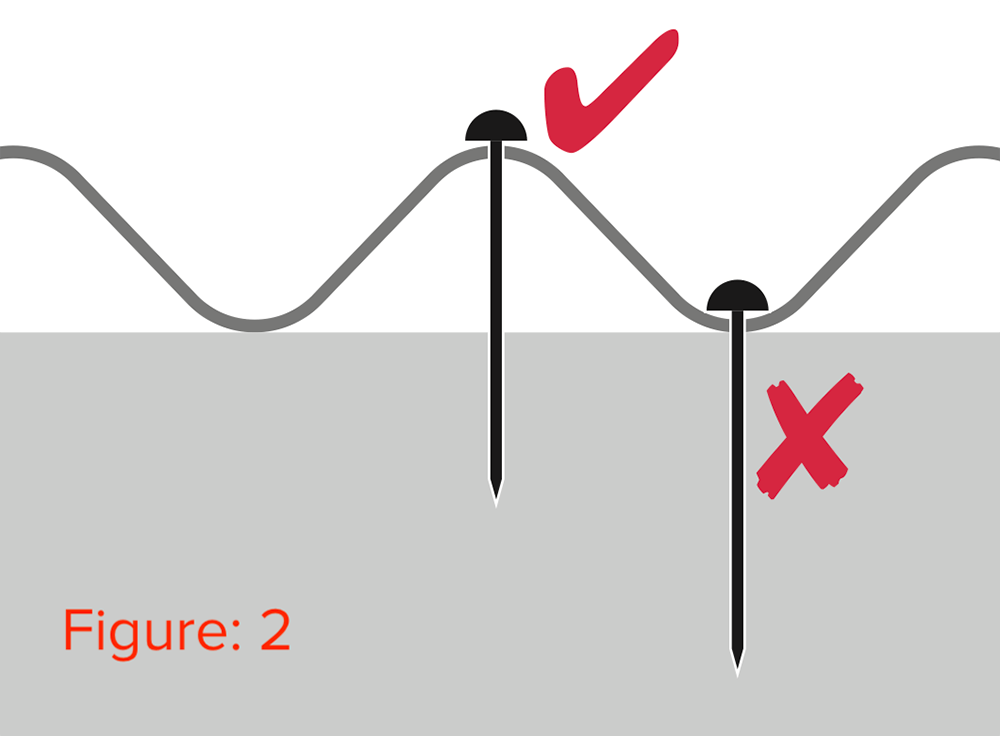

Step 3 - Ensure that you use 'capped' screws or nails to prevent water ingress and, where possible, fix through the 'crown' rather than the 'trough' of the corrugation (Figure 2).

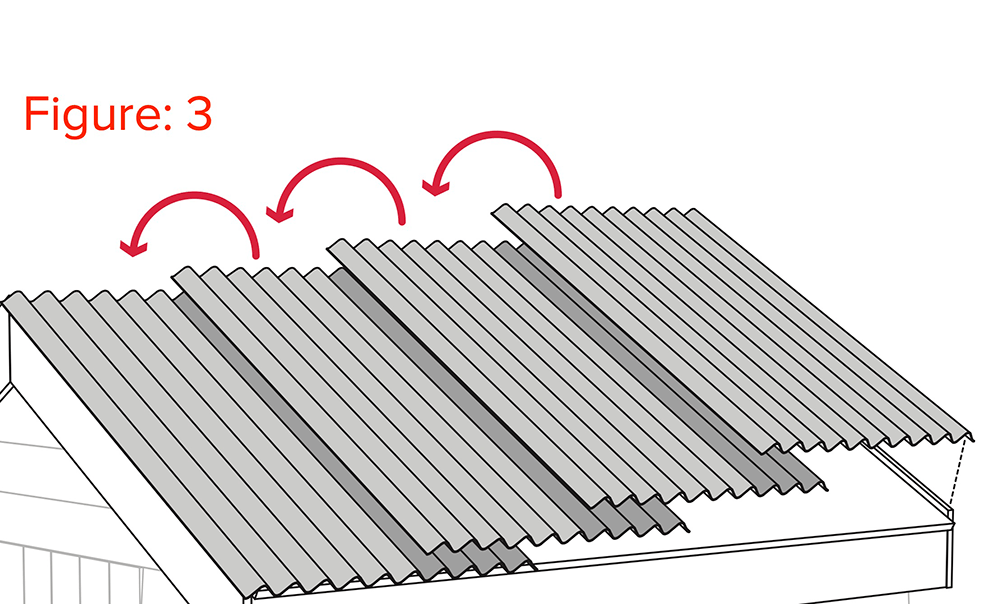

Step 4 - Avoid the necessity for vertical cuts by overlapping roof sheets by more than two corrugations to match the dimensions of the roof exactly (Figure 3).

Step 5 - Use a foam eaves filler of the same profile as the sheet to prevent ingress by weather and insects. Ideally this should be sealed in place with a silicone sealant bead.

Step 6 - When applying ridges (with corrugated bitumen, for example), ensure that you start at the opposite end of the roof to the prevailing wind direction. Overlap the ridges and fix every two corrugations.