Breather membranes (otherwise known as breathable membranes) are used within external wall and roof constructions in order to prevent damp in buildings. BS5250 (clause 8.4.1.1.3) recognises two types of underlay, with breather membranes being defined as “type LR / breathable underlay has a water vapour resistance of less than or equal to 0.25MNs/g”.

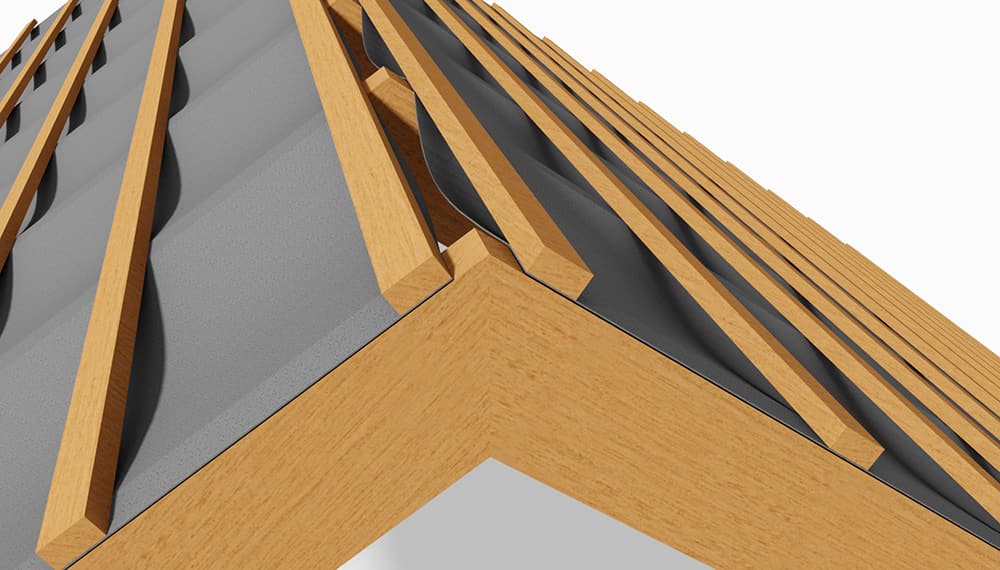

Breather membranes are water-resistant but vapour permeable which means that they can protect your building from damp related issues while releasing any surplus moisture vapour into the air. They are also able to prevent penetration by external environmental factors including snow, wind and rain and they keep out contaminants such as dust and dirt.

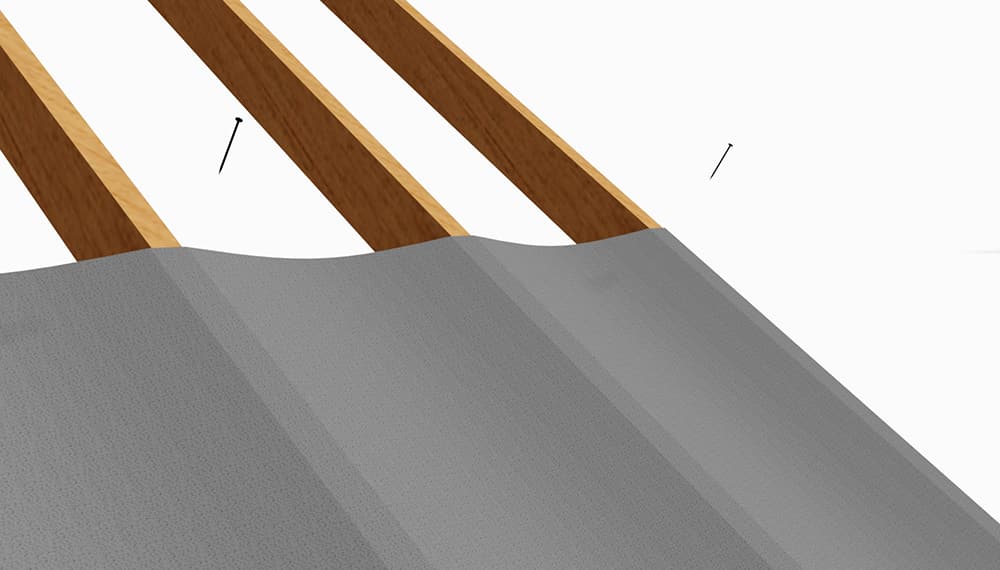

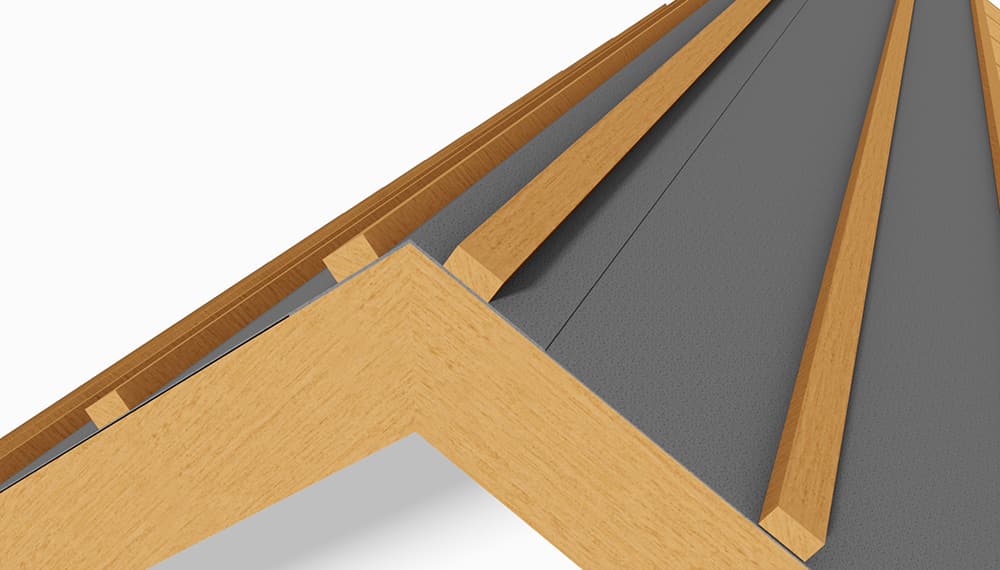

One common problem with homes, especially new builds, is condensation. This can be caused by a number of factors, and a poorly fitted and installed breather membrane can be a contributing factor. Breather membranes are installed to the outer side of the insulation and each roll should contain detailed fitting instructions. You may also need to check the ventilation requirements of the membrane will be met before you begin the installation.

Some breathable membranes are also approved as being air open as well as vapour permeable. These underlays are the most breathable on the market and are particularly suitable where high levels of condensation are to be expected (such as the drying out period of new build properties), or for more complex roofs where traditional ventilation options may be problematic.